Engine Repair

Engine repair is in our roots and runs through our veins. We unburden our clients by providing full-scale engine repair services:

- On-site engine overhaul, maintenance and repair

- In-house engine maintenance and repair in Schiedam

- Wide offer of spare parts and engines

Engine repair, explained

Engine repair

Services

On-site overhaul, maintenance & repair

Due to our skilled 24/7 worldwide operating engineers we are able to provide swift and high quality service, keeping your business in operation. We are a trusted service agent for Yanmar and Zexel.

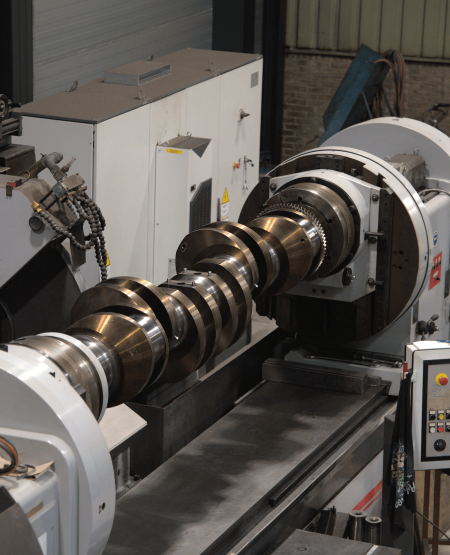

In-house maintenance & repair

Over the last decades we have made extensive investments in our in-house workshop, both in terms of machinery as well as highly skilled manpower, enabling us to provide full-scale engine maintenance and repair services.

Spare parts & engines

Besides on-site and in-house maintenance and repair, Nicoverken also supplies spare parts and engines, enabling us to provide full-service to our customers.

.jpg?resolution=1920x0)